Die Shop Manager Salary in Lewiston, ID

How Much Does a Die Shop Manager make?

Die Shop Manager made a median salary around $85,593 in April, 2025.

The best-paid 25 percent made $111,479 probably that year, while the lowest-paid 25 percent made around $69,872.

Salary ranges can vary widely depending on many important factors, including education, certifications, additional skills, the number of years you have spent in your profession.

With more online, real-time compensation data than any other website, Salary.com helps you determine your exact pay target.

Check out

Die Shop Manager

jobs in

Lewiston, Idaho

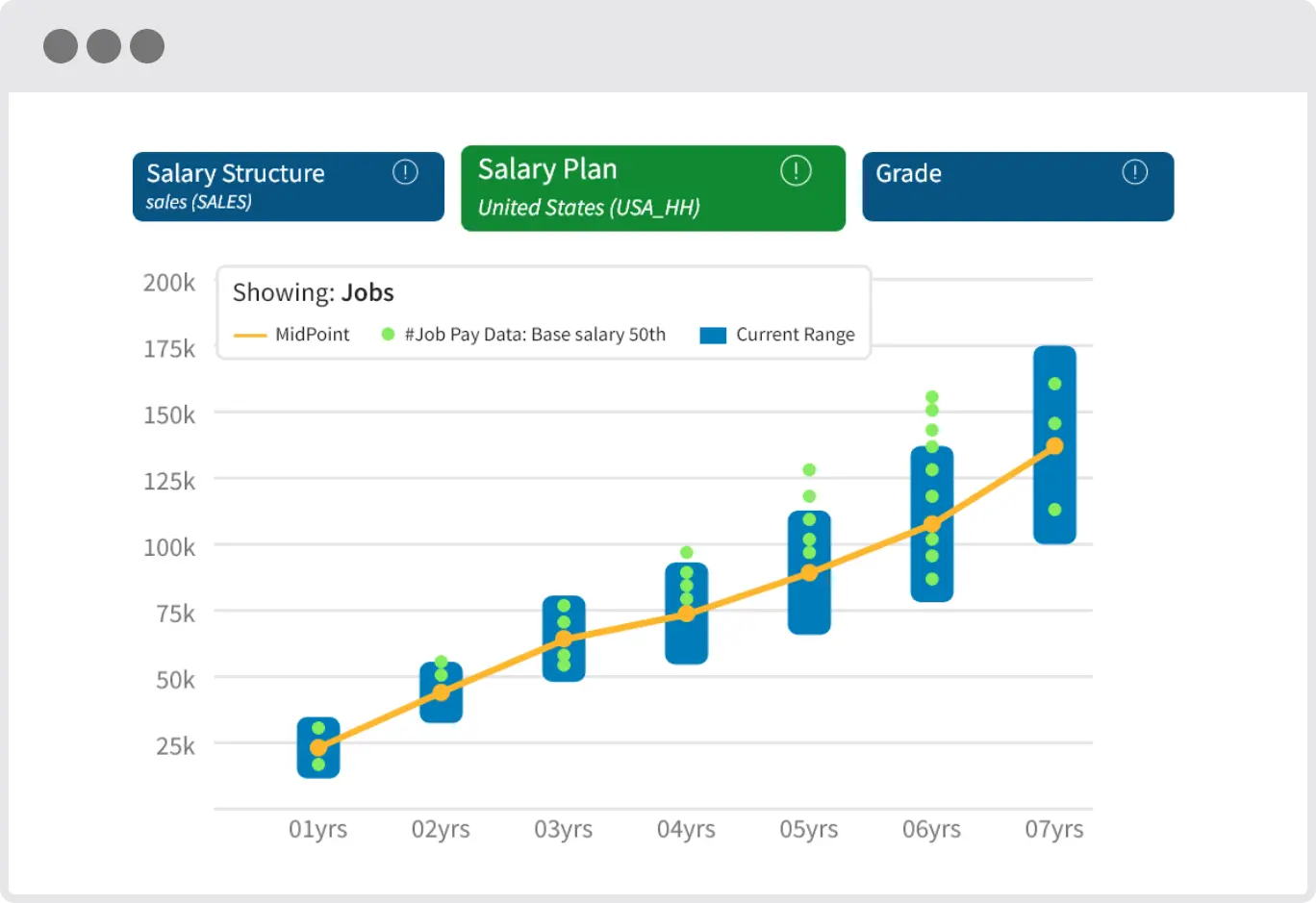

Facing Salary Structure Challenges? Let Our Expert Guide You

The job market is increasingly challenging. Our whitepaper, Navigating the Challenges of Creating Salary Structures, offers guidance on creating salary structures. Provide your phone number and work email to download the full version.

We will handle your contact details in line with our Privacy Policy.

If you prefer not to receive marketing emails from Salary.com, you can opt-out out of marketing communications at any time by clicking unsubscribe.

Best-Paying Cities for Die Shop Manager

The metropolitan areas that pay the highest salary in the Die Shop Manager profession are Lewiston

, Cottonwood

, Fenn

, Grangeville

, Post Falls

.

| Lewiston, ID | $85,593 |

| Cottonwood, ID | $85,593 |

| Fenn, ID | $85,205 |

| Grangeville, ID | $85,205 |

| Post Falls, ID | $83,694 |

Best-Paying States for Die Shop Manager

The states and districts that pay Die Shop Manager the highest salary are District of Columbia (around $91,414)

, California (around $91,067)

, Massachusetts (around $89,853)

, Washington (around $89,523)

, and New Jersey (around $89,490)

.

| District of Columbia | $91,414 |

| California | $91,067 |

| Massachusetts | $89,853 |

| Washington | $89,523 |

| New Jersey | $89,490 |

Frequently Asked Questions for Die Shop Manager

Q:

What is the salary range of Die Shop Manager in Lewiston, ID?

A:

In 2025

, the lowest-paid Die Shop Manager in Lewiston, ID earned an average annual salary of $69,872

, while the highest-paid made $111,479.

Q:

What is the salary for a Die Shop Manager in California?

A:

Die Shop Manager employed in California earned an average salary of $91,067 in 2025.

Average Die Shop Manager Pay vs. Other Jobs

Die Shop Manager earned an average salary of $85,593 in 2025.

Other jobs related to Die Shop Manager earned the following average salary in April, 2025.

Machine Shop Tool & Die Maker I

made $65,200

,

Machine Shop Tool & Die Maker II

made $67,100

,

Machine Shop Tool & Die Maker III

and

Tool and Die Maker I

made $75,800

and $65,136 respectively

.

Relevant Jobs of Die Shop Manager

The Machine Shop Tool & Die Maker I works from blueprints and sketches to create or modify prototypes, tools, dies, jigs, fixtures and molds. Builds and repairs custom machine shop tools using machining equipment and measuring instruments. Being a Machine Shop Tool & Die Maker I operates lathes, grinders, milling, and boring machines to produce tools. Calculates the dimensions and tolerances required to set up the machine tools. In addition, Machine Shop Tool & Die Maker I generally is participating in an apprenticeship or on the job training program. May require an associate's degree or its equivalent. Typically reports to a supervisor or manager. May require Apprenticeship certificate. Being a Machine Shop Tool & Die Maker I gains or has attained full proficiency in a specific area of discipline. Works under moderate supervision. Working as a Machine Shop Tool & Die Maker I typically requires 1-3 years of related experience.

The Machine Shop Tool & Die Maker II works from blueprints and sketches to create or modify prototypes, tools, dies, jigs, fixtures and molds. Builds and repairs custom machine shop tools using machining equipment and measuring instruments. Being a Machine Shop Tool & Die Maker II operates lathes, grinders, milling, and boring machines to produce tools. Calculates the dimensions and tolerances required to set up the machine tools. In addition, Machine Shop Tool & Die Maker II generally is participating in and has completed initial phases of an apprenticeship or on the job training program. May require an associate's degree or its equivalent. Typically reports to a supervisor or manager. May require Apprenticeship certificate. Being a Machine Shop Tool & Die Maker II has gained proficiency in multiple competencies relevant to the job. Works independently within established procedures associated with the specific job function. Working as a Machine Shop Tool & Die Maker II typically requires 3-5 years of related experience.

The Machine Shop Tool & Die Maker III works from blueprints and sketches to create or modify prototypes, tools, dies, jigs, fixtures and molds. Builds and repairs custom machine shop tools using machining equipment and measuring instruments. Being a Machine Shop Tool & Die Maker III operates lathes, grinders, milling, and boring machines to produce tools. Calculates the dimensions and tolerances required to set up the machine tools. In addition, Machine Shop Tool & Die Maker III generally has completed an apprenticeship or on the job training program. May require an associate's degree or its equivalent. Typically reports to a supervisor or manager. May require Apprenticeship certificate. Being a Machine Shop Tool & Die Maker III has gained full proficiency in a broad range of activities related to the job. Independently performs a wide range of complex duties under general guidance from supervisors. Working as a Machine Shop Tool & Die Maker III typically requires 5-7 years of related experience.

Builds and repairs custom machine shop tools using machining equipment and measuring instruments. Works from blueprints and sketches to create or modify prototypes, tools, dies, jigs, fixtures and molds. Calculates the dimensions and tolerances required to set up the machine tools. Operates lathes, grinders, milling, and boring machines to produce tools. Generally is participating in an apprenticeship or on the job training program. May require an associate degree or equivalent. Typically reports to a supervisor or manager. Works under moderate supervision. Gaining or has attained full proficiency in a specific area of discipline. Typically requires 1-3 years of related experience.

Builds and repairs custom machine shop tools using machining equipment and measuring instruments. Works from blueprints and sketches to create or modify prototypes, tools, dies, jigs, fixtures and molds. Calculates the dimensions and tolerances required to set up the machine tools. Operates lathes, grinders, milling, and boring machines to produce tools. Generally is participating in and has completed initial phases of an apprenticeship or on the job training program. May require an associate degree or equivalent. Typically reports to a supervisor or manager. Works independently within established procedures associated with the specific job function. Has gained proficiency in multiple competencies relevant to the job. Typically requires 3-5 years of related experience.